- Plastic Sheet

- Engineering Plastics

- Architectural Products

- Plastic Welding

- Chemicals & Polymers

- Industry Search

| Privacy policy | Terms of Conditions of Sale |

Designed by Openseed Digital Consultancy

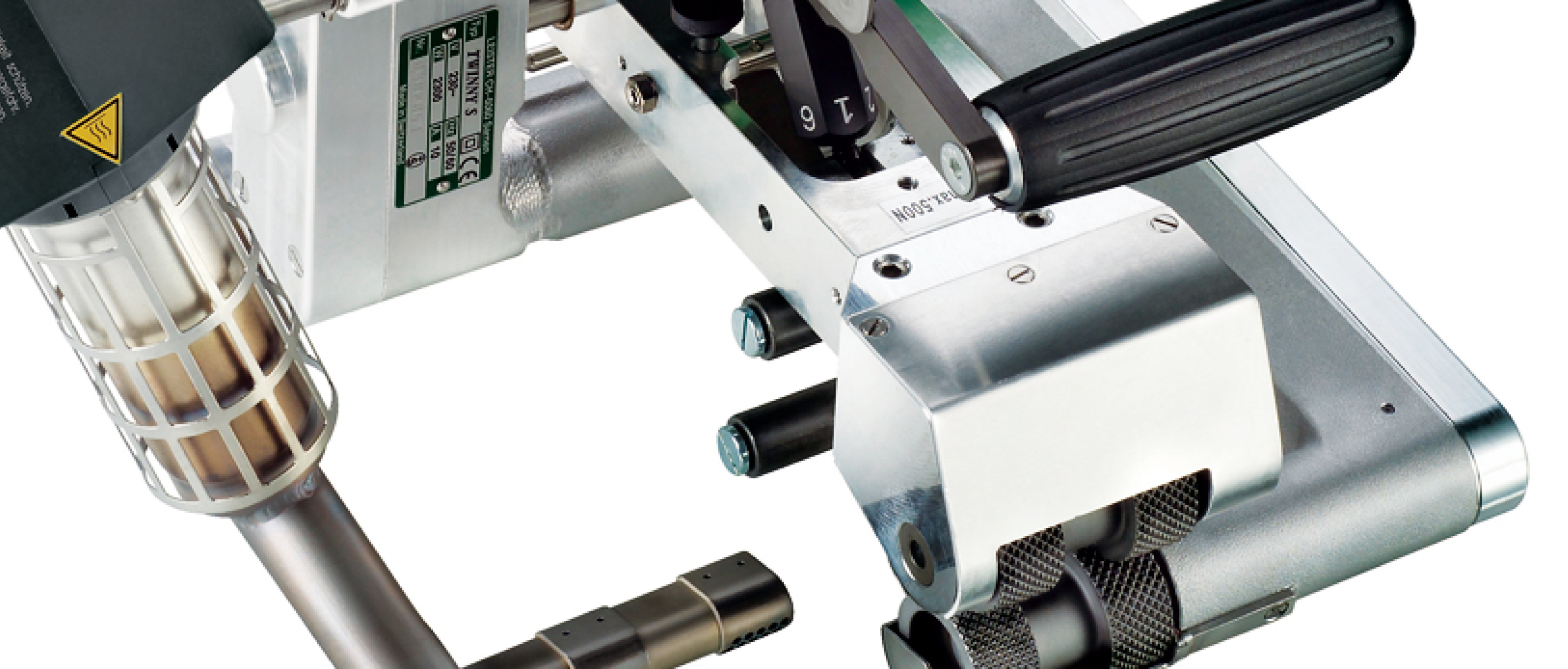

PVC Membrane Welding is made easy with the handy and compact Leister Twinny S.

Weighing just 6.9kg, the Twinny S is ideal for welding fine membranes and thin materials used mainly in tunnel construction, dam liner welding and other civil engineering processes.

The PVC membrane welding machine is optimised to provide seamless welding even when it is used by operators with little to no training. The lightweight tool is very easy to use, thanks to the ergonomic design which makes its handling and operation easy while also providing quality results.

Leister Twinny S can be fitted with an extremely lightweight cross handle, making overhead welding easy and comfortable. The machine is capable of producing perfect welds even in the most unforgiving site conditions, making it highly suitable for dam liner welding and tunnel construction. The class-leading hot-air delivery system used in the machine makes high-speed welding possible without compromising the quality of the weld.

The lightweight welding tool comes with a temperature and drive control to suit a variety of welding jobs and conditions. To make it further compatible with the intended use of the operator, Leister offers to provide a number of replaceable combi-wedges which can be ordered with/without a test channel.

The Leister Twinny S PVC Membrane Welding Machine comes with the following features:

The Leister Twinny S PVC Membrane Welding Machine provides the following applications:

For further information or to speak to a Plastral representative about this product, please contact us here.

Auckland, New Zealand

Building 10, 666 Great South Road, Penrose 1061

Auckland, New Zealand

Building 10, 666 Great South Road, Penrose 1061